UvLack: The Revolutionary UV Coating Technology

In today’s competitive industrial landscape, the right coating solution can make or break a product’s performance and visual appeal. Enter UvLack, a revolutionary UV coating technology that is redefining the standards of durability, aesthetics, and environmental responsibility. Unlike traditional coatings, UvLack provides an unmatched combination of long-lasting protection, stunning finishes, and eco-friendly benefits, making it a preferred choice for manufacturers, designers, and hobbyists alike.

The significance of UvLack extends far beyond surface protection. Its advanced formulation allows for quick curing, reducing production time while ensuring a flawless finish. Whether applied to automotive interiors, high-end furniture, electronic devices, or packaging materials, UvLack consistently delivers a high-quality result that resists scratches, fading, and chemical damage.

What truly sets UvLack apart is its eco-conscious design. With low volatile organic compound (VOC) emissions and energy-efficient UV curing, it aligns with modern sustainability goals without compromising performance. From automotive to electronics, UvLack is transforming industries by combining speed, style, and strength, making it a game-changer in surface finishing solutions.

What is UvLack?

UvLack is an advanced ultraviolet (UV) coating designed to enhance both durability and aesthetics of various surfaces. Unlike conventional coatings that may require hours or even days to dry, UvLack cures almost instantly when exposed to UV light, forming a tough, resilient layer that protects against physical and environmental damage.

Key Features of UvLack:

- UV Curing: Rapid curing process reduces production downtime and ensures uniform coatings.

- Glossy Finish: Provides a smooth, high-gloss finish that enhances color vibrancy and overall appearance.

- Durability: Resistant to scratches, chemicals, heat, and UV exposure, prolonging product lifespan.

Eco-Friendly Nature:

UvLack is formulated with low VOC emissions, which not only make it safer for workers during application but also reduce environmental impact. Its energy-efficient curing process further emphasizes sustainable manufacturing practices, making it an ideal choice for industries aiming to balance performance with environmental responsibility.

By combining efficiency, protection, and visual appeal, UvLack has quickly become a preferred coating solution across a wide range of industrial and creative applications.

The Science Behind UvLack

The effectiveness of UvLack lies in its advanced chemical composition and UV curing technology. The coating is primarily made up of:

- Polymers: Provide flexibility and adhesion, ensuring the coating bonds securely to different substrates.

- Photoinitiators: Chemicals that react when exposed to UV light, triggering rapid polymerization.

- Additives: Enhance specific properties like scratch resistance, gloss, chemical resistance, and UV stability.

How UV Curing Works:

When UvLack is exposed to UV light, photoinitiators initiate a chemical reaction called polymerization, rapidly transforming the liquid coating into a solid, cross-linked protective layer. This process takes only seconds to minutes, compared to traditional coatings that require hours to dry. The cross-linked structure enhances durability, making surfaces highly resistant to wear, moisture, and chemical exposure.

Benefits of UvLack’s Science:

- Scratch Resistance: Protects high-traffic surfaces from daily wear and tear.

- Chemical Resistance: Safeguards materials from exposure to cleaning agents and industrial chemicals.

- Long-Lasting Finish: Maintains gloss and integrity over extended periods.

Aesthetic Impact:

UvLack’s formulation enhances clarity and gloss, making colors more vivid and surfaces visually striking. The combination of strength and beauty ensures that products are not only protected but also visually appealing—a key factor in industries like furniture, automotive, and electronics.

Historical Development of UV Coatings

Before the rise of UV technology, traditional coatings were limited by long drying times, uneven finishes, and environmental concerns due to high VOC emissions. Industries faced significant challenges in balancing durability, aesthetics, and sustainability.

The emergence of UV curing technology marked a turning point. By utilizing ultraviolet light to solidify coatings, manufacturers could achieve rapid curing without compromising quality. This innovation significantly increased production efficiency while producing stronger, more resilient finishes.

Over time, formulations evolved. Early UV coatings often lacked adhesion or flexibility, but modern products like UvLack incorporate advanced polymers and additives that enhance scratch resistance, adhesion, and gloss retention. At the same time, there has been a growing emphasis on sustainability, leading to low-VOC formulations and energy-efficient curing processes.

Today, UV coatings like UvLack represent the modern standard for high-performance finishes, offering industries a solution that balances speed, strength, aesthetics, and environmental responsibility.

Applications of UvLack Across Industries

Automotive:

UvLack is widely used to protect dashboards, trims, and exterior parts. Its resistance to UV rays, chemicals, and scratches ensures vehicles maintain a high-end appearance over time.

Furniture & Interior Design:

From dining tables to cabinetry, UvLack provides glossy, scratch-resistant finishes that preserve wood’s natural beauty while adding durability for high-traffic areas.

Electronics:

Delicate components, including smartphones, laptops, and circuit boards, benefit from UvLack’s protective coating. It shields devices from moisture, dust, and scratches without compromising aesthetic appeal.

Packaging & Printing:

Boxes, labels, and printed materials gain a high-gloss, scratch-resistant layer that enhances visual appeal while protecting against wear during transport or handling.

Construction & Art Restoration:

UvLack is used for protective coatings on various construction materials and artwork, offering long-lasting protection while maintaining visual clarity and aesthetic quality.

Across these sectors, UvLack’s versatility and high-performance properties make it an indispensable tool for modern manufacturers and creators.

Benefits of UvLack

Durability:

UvLack forms a robust protective layer that resists scratches, heat, chemicals, and UV exposure, significantly extending the lifespan of treated surfaces.

Aesthetics:

Available in glossy, satin, or matte finishes, UvLack enhances color vibrancy and depth, making surfaces visually striking while maintaining clarity and gloss over time.

Efficiency:

Rapid UV curing reduces production time, increases throughput, and minimizes downtime in manufacturing processes.

Versatility:

UvLack adheres to a wide range of materials, including wood, metal, plastic, glass, and composites, making it suitable for diverse industries.

Environmental Advantages:

Low VOC emissions and energy-efficient curing make UvLack a greener alternative to traditional coatings. Its eco-friendly profile ensures compliance with modern environmental standards while reducing industrial impact.

By combining protection, beauty, and sustainability, UvLack has emerged as a leading solution in modern coatings technology, offering measurable benefits for manufacturers, designers, and end-users alike.

How to Apply and Use UvLack

Applying UvLack correctly is crucial to achieve its full potential in durability, aesthetics, and protection. Following the right steps ensures an even, long-lasting finish.

Surface Preparation:

Before applying UvLack, ensure the surface is clean, dry, and free of dust, grease, or contaminants. Wipe the area with a lint-free cloth and a mild cleaner. Proper surface preparation is essential, as any residual particles can compromise adhesion and lead to uneven finishes.

Application Techniques:

UvLack can be applied using various methods depending on the size and complexity of the surface:

- Spray: Ideal for large or intricate surfaces, providing even coverage without streaks.

- Brush: Suitable for small areas or detailed work, ensuring precise application.

- Roller: Best for flat surfaces where uniform thickness is essential.

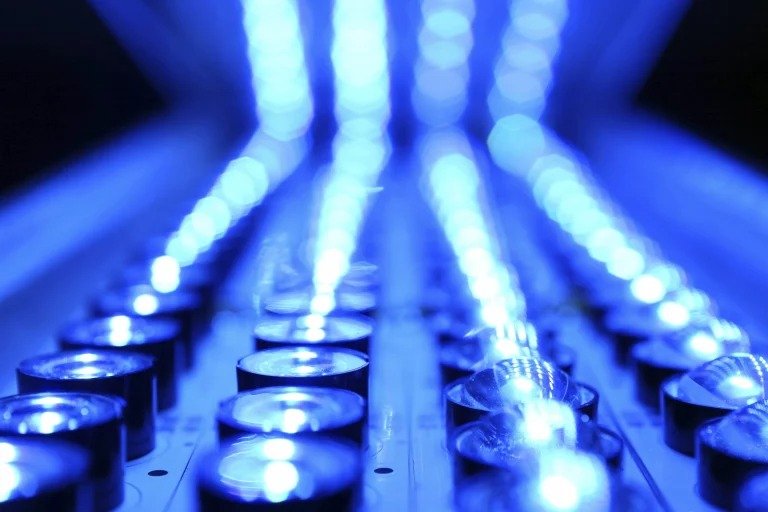

UV Curing Process:

Once applied, the coating must be exposed to ultraviolet light to cure. The exposure time depends on the coating thickness and UV light intensity, typically ranging from 30 seconds to a few minutes. Ensure that the light evenly reaches all areas, and avoid shaded spots that could prevent proper curing. Using UV-curing chambers or LED UV lamps enhances efficiency and ensures consistent results.

Maintenance Tips:

- Clean surfaces with soft cloths and mild detergents to avoid scratches.

- Avoid harsh chemicals that may compromise the protective layer.

- Regularly inspect high-traffic areas and reapply UvLack if necessary to maintain optimal protection and aesthetics.

Proper application and maintenance ensure that UvLack provides long-lasting protection while preserving its glossy, vibrant finish.

Comparison with Traditional Coatings

Curing Time:

Traditional coatings often require hours or days to dry, leading to longer production cycles. UvLack cures within minutes under UV light, significantly improving efficiency and reducing downtime.

Durability and Scratch Resistance:

While conventional coatings may chip, fade, or peel over time, UvLack’s cross-linked polymer network offers superior scratch resistance and long-term protection against environmental factors.

Environmental Impact:

Traditional coatings often contain high levels of VOCs, posing health risks and contributing to environmental pollution. UvLack is low-VOC and energy-efficient, making it a greener choice for modern manufacturing.

Cost-Benefit Analysis:

Although UV coating systems and equipment require an initial investment, the long-term benefits include reduced reapplication, fewer defects, and lower maintenance costs. Businesses save money over time while improving product quality and customer satisfaction.

This comparison highlights why UvLack is a forward-looking solution that outperforms conventional coatings in durability, aesthetics, and sustainability.

Industry Feedback and Case Studies

Automotive:

A leading car manufacturer reported that using UvLack on interior trims and dashboards reduced wear and tear while maintaining high gloss for years. Customers appreciated the vibrant appearance and scratch-resistant surfaces, enhancing overall brand perception.

Furniture:

A furniture company shared that UvLack allowed them to achieve durable, high-gloss finishes on tables and cabinets, reducing returns due to scratches or fading. Production times decreased thanks to rapid UV curing.

Electronics:

Electronics manufacturers applied UvLack to smartphones and laptops, noting improved resistance to dust and moisture without compromising visual clarity. Devices maintained a premium look even after prolonged use.

Art Restoration:

Art studios used UvLack to protect restored paintings and sculptures. The coating preserved colors and textures while providing a protective layer against UV exposure and environmental pollutants.

Overall, testimonials and case studies consistently highlight efficiency, durability, and aesthetic enhancement, demonstrating UvLack’s tangible benefits across diverse industries.

Challenges and Considerations

Initial Investment:

Setting up UV curing equipment may require a higher upfront cost compared to traditional methods. However, the long-term savings from reduced rework and faster production offset this investment.

Limitations on Uneven or Shaded Surfaces:

UvLack requires consistent UV exposure for proper curing. Uneven surfaces or areas blocked from UV light may cure incompletely, resulting in weaker protection. Special attention is needed during application to avoid missed spots.

Precision Required:

Application must be uniform and controlled. Over-application or pooling can lead to imperfections such as streaks or bubbles. Proper training and practice are necessary for optimal results.

By addressing these considerations, businesses can maximize the benefits of UvLack while minimizing potential challenges.

Innovations and Future Potential

UvLack technology continues to evolve, promising exciting future developments:

- Anti-Fingerprint and Hybrid Nanotechnology Coatings: Advanced formulas reduce smudging and improve surface resistance to dust, oils, and fingerprints.

- AI-Controlled Curing Systems: Automated curing processes using AI ensure precise exposure, reducing human error and enhancing efficiency.

- Expansion into Renewable Energy Equipment: UvLack coatings are being explored for solar panels and wind turbine components, providing UV protection and longevity in harsh outdoor conditions.

- Smart and Functional Coatings: Research is ongoing to integrate features like antimicrobial protection and self-cleaning surfaces, expanding UvLack’s industrial applications further.

These innovations suggest that UvLack is not just a product but a platform for continuous improvement, making it adaptable for emerging technologies and industry needs.

Conclusion

UvLack is more than just a coating; it’s a comprehensive solution that blends durability, aesthetics, eco-friendliness, and versatility. Its rapid UV curing process, high gloss finish, and resistance to scratches, chemicals, and UV rays make it a standout choice across multiple industries, from automotive and furniture to electronics, packaging, and art restoration.

By integrating UvLack into your processes, you can enhance product quality, reduce production time, and achieve superior finishes that elevate brand perception. Its low VOC emissions and energy-efficient application align with modern sustainability goals, making it a responsible choice for environmentally conscious manufacturers.

As industries demand smarter, faster, and more resilient solutions, UvLack continues to lead the way, offering innovative features and adaptability for the future. Adopting UvLack is not just an investment in a coating—it’s an investment in long-lasting quality, visual appeal, and sustainable innovation.